Northvolt's approach to sourcing cathode battery materials

5 February, 2025

Transforming supply chains is integral to developing a sustainable battery industry. Here we outline our supplier selection process and efforts to maintain a robust supply chain amidst challenges.

Transforming supply chains is integral to developing a sustainable battery industry. We prioritize partnerships that align with our commitment to sustainability while supporting our operations and growth. Although we have revised our strategic direction as a company, we remain committed to developing a sustainable battery value chain. Here we outline our supplier selection process and efforts to maintain a robust supply chain.

Cathode active material sourcing at Northvolt

To date, Northvolt has sourced cathode active material for its cell production from external parties. This model — the conventional approach of cell manufacturers — has been in place whilst Northvolt worked to establish in-house cathode active material production.

Our cathode active material production took place at Northvolt Ett Upstream 1 facility, which was fully built, installed and producing battery-grade material as it approached its end of commissioning.

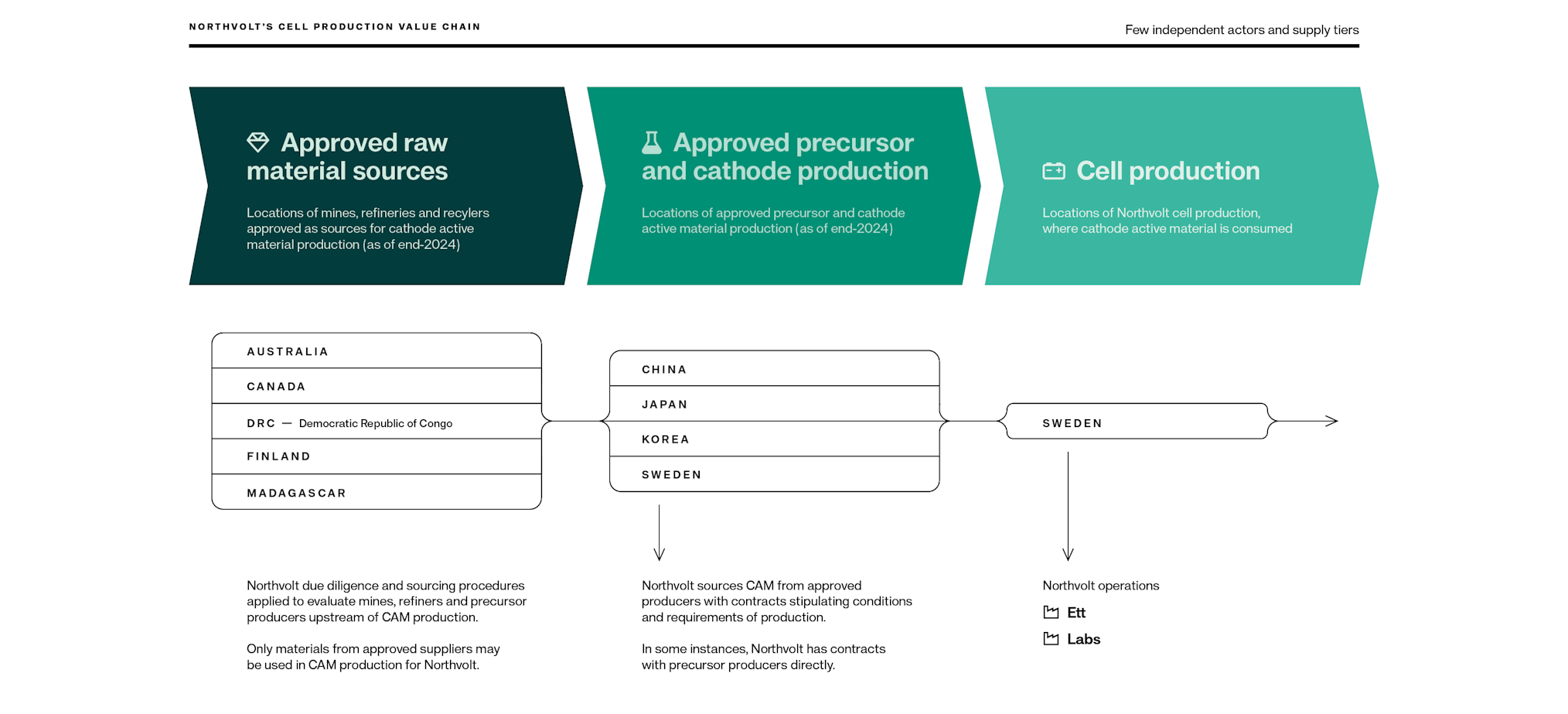

Vertical integration of cathode active material production and cell production into in-house operations enables direct sourcing of raw materials from mines and refineries to create a simplified, traceable and transparent supply chain, with higher degree of control on environmental and social standards.

As of October 2024, we suspended activities at Upstream 1 as part of Northvolt’s strategic review, which focussed resources on our core business of cell manufacturing.

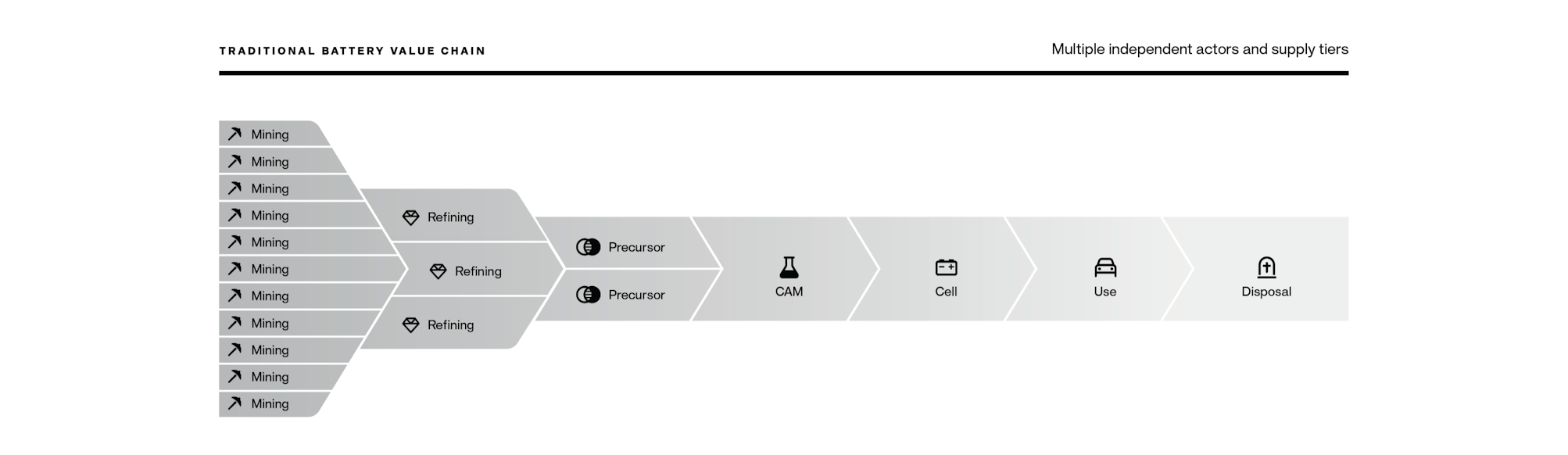

As we explore partnerships to continue upstream activities, Northvolt’s cell production will continue to rely on externally sourced cathode active material. Sourcing cathode active material externally presents challenges to our sustainability ambitions. Blending at various stages of the supply chain reduces physical traceability, making it harder to verify the origin of materials and increasing the risk of exposure to human rights and environmental violations.

Additionally, the involvement of multiple intermediaries negatively impacts our ability to control the carbon footprint of production; this is particularly concerning as most cathode active material producers are based in Asia, with carbon intensive grids powering production. We have calculated that the use of external cathode active material will initially result in an approximate increase of 10 kg CO2e/ kWh compared to the projected carbon footprint of cells produced with internally produced material — a difference we aim to eliminate in the coming few years.

Despite the challenges, Northvolt maintains the same expectations for its externally sourced cathode material value chain as for its internal cathode active material. Our approach incorporates specific controls to ensure that the materials are produced with high standards surrounding the environment and human rights. This includes due diligence on environmental and social aspects throughout the value chain down to mine level, regulating which raw material sources cathode producers may use, as well as setting requirements on our suppliers regarding the use of fossil-free energy, recycled content and carbon emission reduction.

Northvolt’s approach for sourcing materials responsibly

Northvolt is committed to responsible material sourcing. We strive for full transparency in our supply chains down to the level of the mine and conduct due diligence at every step. Our responsible sourcing framework is risk-based and follows OECD Due Diligence Guidelines. Additionally, we incorporate other international frameworks such as the IFC Performance Standards and UN Guiding Principles on Business and Human Rights, amongst others.

We select all suppliers based on their alignment with Northvolt targets and principles, including those providing raw materials to our external cathode active material suppliers. All direct suppliers are required to adhere to Northvolt’s Supplier Code of Conduct. In high-risk countries, we supplement our evaluations with third-party audits to assess compliance with our standards. Where gaps are identified, we implement corrective action plans and re-assess suppliers to ensure consistent performance and/or improvement.

To verify the chain of custody of the materials, our assessments of suppliers evaluate both traceability and due diligence processes. This includes reviewing how suppliers manage risks and track materials in their production and verify disclosed supply chain maps against purchasing records.

Contracts with cathode active material suppliers stipulate that only Northvolt-approved raw material sources may be used, using a mass balance chain of custody approach. We collect data from our supply chain to monitor that no additional sources are used which have not been approved by Northvolt.

Northvolt’s approach to responsible sourcing, as described here, has been externally assessed, and is well-aligned with customers' and EU Battery Regulation requirements.

As of 2024, our approved raw material sources for use in our externally sourced cathode were sufficient to meet our demand (see figure below). Looking ahead, we are conducting due diligence on additional sources to meet our growing production needs. We are actively exploring the possibility to source from Indonesia and will apply the same engagement-driven approach we have used in the Democratic Republic of Congo (DRC) to ensure compliance with Northvolt standards, drive improvements and promote sustainable practices.

Visualizing Northvolt's approach to sourcing raw materials

Traditional battery value chain

Our commitment to the DRC

Today, the majority of the cobalt in our externally sourced cathode active material (and therefore in our cells) originates from locations outside of the Democratic Republic of Congo (DRC). Only a small portion of the cobalt originates from Northvolt-approved mines and smelters in the southern part of the DRC — a region not affected by the recent escalations in conflict in the North Kivu province.

While our use of cobalt from the DRC is relatively low, we have taken a careful and deliberate approach to our engagement in the nation. We began exploring responsible cobalt sourcing from the DRC several years ago. During recent years, we have engaged with local stakeholders, including mines, NGOs, and other groups, to gain insights into the local supply chain and broader ecosystem.

To support ongoing stakeholder engagement, we joined the Fair Cobalt Alliance (FCA) and the Cobalt Institute. The FCA works to professionalize the DRC’s artisanal and small-scale mining sector and promote local economic development. The Cobalt Institute promotes sustainable and responsible production and use of cobalt across industries through advocacy, research, and collaboration.

Within the DRC, we have conducted extensive due diligence, including site visits and supplier engagement, to assess alignment with our environmental and social standards, and identify and implement improvement measures. Through these efforts, we qualified specific DRC mines for inclusion within our supply chain. As standard practice, we continue to monitor and assess DRC cobalt sources, alongside those outside the DRC, to ensure compliance with our standards. While we do not buy artisanal mined cobalt – rather, we have approved selected, large-scale mines – we believe it is crucial for us to engage on this matter as an end-consumer of cobalt from the region.

The work ahead

While sourcing externally produced cathode active materials presents additional challenges compared to using internally produced cathode, Northvolt remains steadfast in its sustainability, circularity and responsible sourcing ambitions.

By maintaining high standards, collaborating with stakeholders, and driving improvements across the value chain, we continue to prioritize environmental and human rights considerations in all aspects of our operations. In parallel, Northvolt continues to plan for a restart of the internal cathode production together with partners over time. Through these efforts, we aim to continue on our work to establish a sustainable and transparent battery industry.