NorthFlex Project - Decarbonising temporary power and flexible storage

3 March, 2023

Northvolt Systems presents the NorthFlex Project, supported by The EU Innovation Fund, with the central aim of cutting emissions from temporary and industrial scale energy storage. The project introduces an innovative mobile battery system technology to the market, with a planned entry into operation in 2024.

1. Project overview

The green energy transition is a global objective and a priority for the European Union (EU), especially after the European Green Deal, which introduced new ambitious CO2e reduction targets. To increase electrification, despite increased variability in the grid power supply and limitations in grid power connections – Northvolt Systems, will develop a mobile and scalable battery energy storage system, as part of the NorthFlex Project.

The NorthFlex Project objective is to introduce to the market, and scale-up the deployment of, an innovative battery system technology. The project entails development, design, and manufacturing of a scalable battery energy storage system (BESS) as well as the expansion of Northvolt’s battery systems manufacturing capabilities in Gdánsk, Poland.

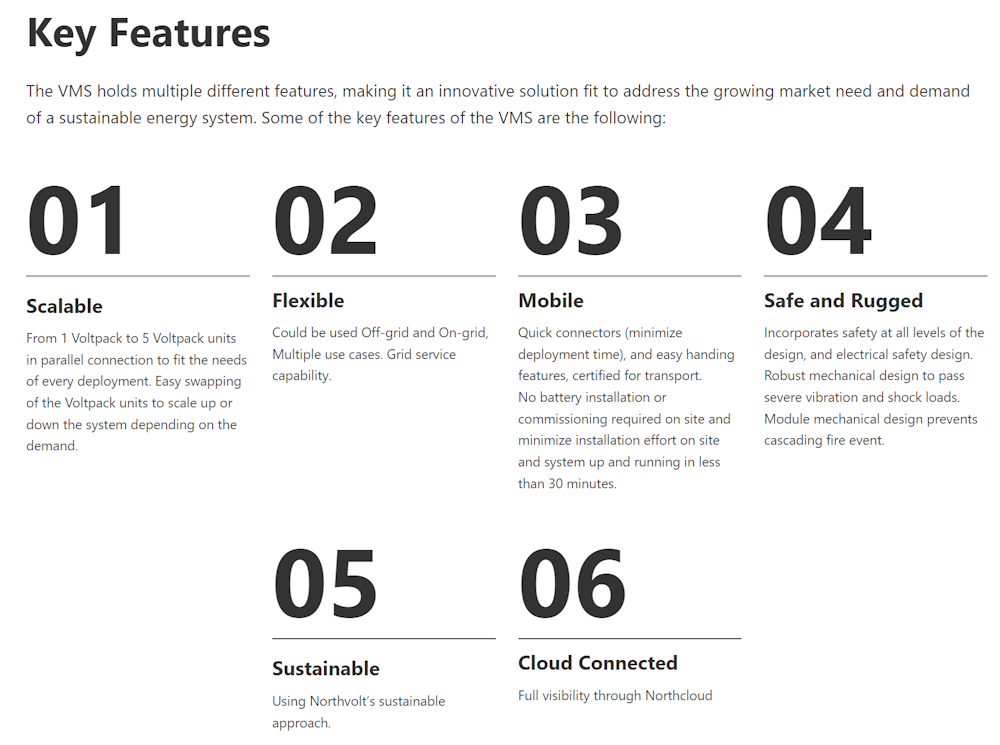

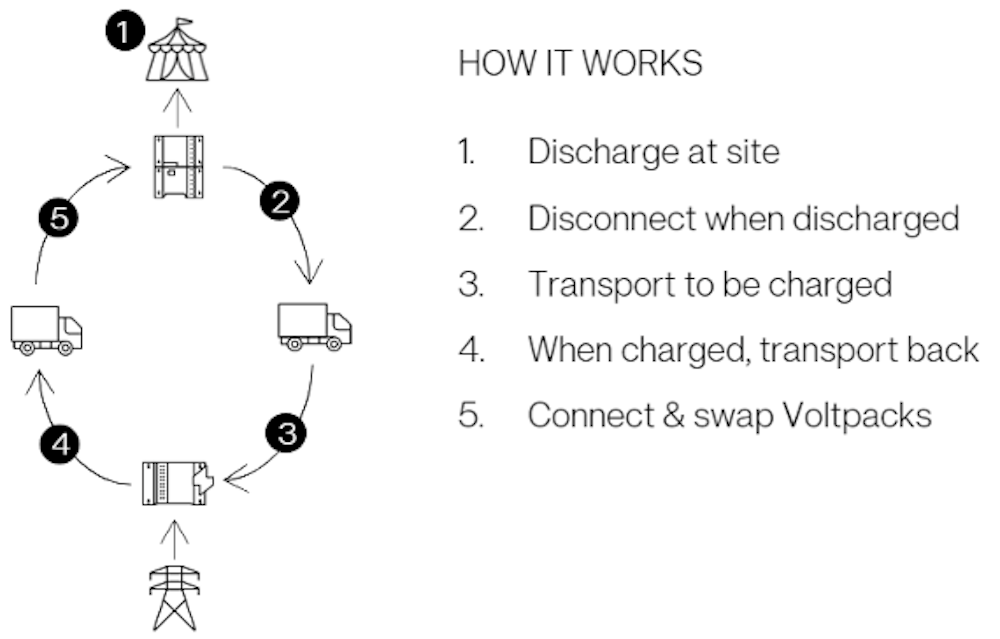

The battery energy storage system (BESS), referred to as the Voltpack Mobile System (VMS), comprises of two units: An individual high energy-density battery pack: the Voltpack Mobile, and a central power conversion unit: the Volthub Grid. Through the combination of both units, the VMS is a plug-and-play solution with fully integrated power technology.

The VMS is a plug-and-play energy storage system with fully integrated power technology. It has a modular, mobile, and scalable design, fitting for rapid deployment within multiple applications. A single Voltpack Mobile unit has an energy capacity of 281 kWh – and the system can be scaled up to 1,405 kWh, to fit various energy and power needs.

COORDINATOR - Northvolt Systems

LOCATION - Poland and Sweden

STARTING DATE - 01 April 2021

PLANNED DATE OF ENTRY INTO OPERATION - Q2 2024

The VMS is introduced in anticipation as part of the green energy transition in Europe by offering a direct replacement to CO2 intensive diesel generators as well as providing a sustainable and flexible solution for commercial or industrial scale energy storage within new market applications. The scale-up of the sustainable, high-energy, and high-power battery system will support increased electrification, while augmenting further adoption of renewable power sources to achieve net zero CO2e emissions by 2050.

2. Innovation design

The NorthFlex project introduces innovation both in the product design and in the manufacturing process. With high energy density, enhanced performance, strong safety features, as well as a mobile and modular design, Northvolt Systems presents an innovative product solution, fitting for various market applications. Moreover, with a highly automized, digitalized and vertically integrated manufacturing process, Northvolt allows for full traceability of all components as well as augmented reuse and recycling of products and raw materials.

The VMS consists of two separate units: The Voltpack Mobile (Voltpack) and the Volthub Grid (Hub):

Voltpack: The Voltpack is an individual self-contained, industrial-grade, high energy-density Lithium-ion BESS with an installed capacity of 281 kWh per unit.

Hub: The Hub is the central power conversion hub, providing a 400 VAC pluggable input and output. This allows the BESS to interface with all standard distribution equipment.

How does it work?

The system scales through a central interface Hub, which can connect in parallel up to five self-contained Voltpacks, each containing three liquid-cooled, industrial-grade battery packs, referred to as Voltpack Core. The Hub also serves as an interface for applications, and houses inverter and auxiliary systems. If further power or storage capacity is needed, this can be fulfilled simply by connecting multiple Voltpacks in parallel. The system is scalable from 281 kWh to 1,405 kWh.

Thanks to several types of connections, the system can, e.g.:

- Create a standalone grid through the inverter’s voltage source mode (Island Mode)

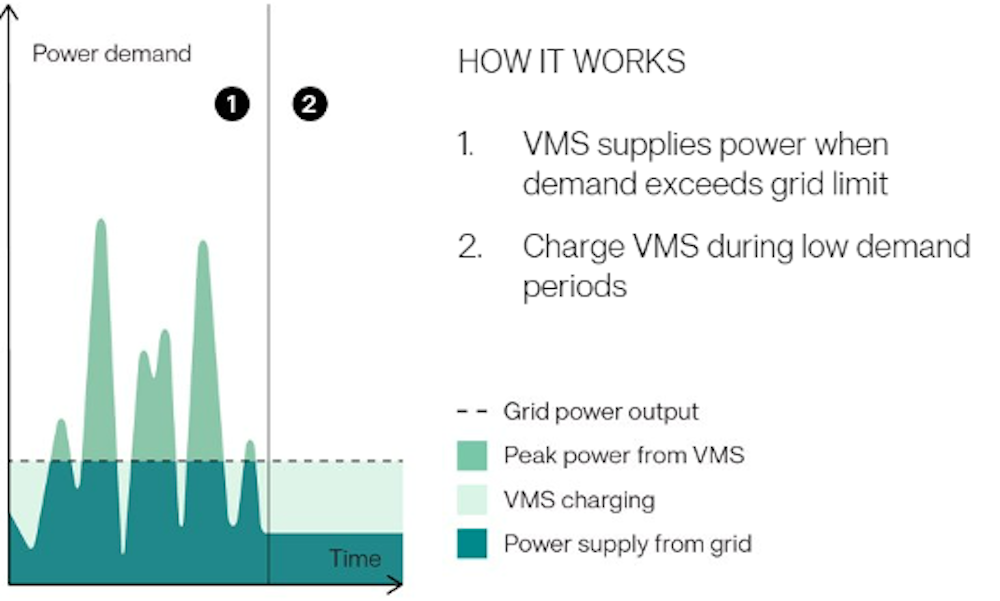

- Peak shave to support short busts in power demand (Rapid Peak Shaving Mode)

- Integrate solar or wind power generation into a grid (Migrogrid Mode)

- Generate electricity off-peak to store and sell at peak price (Grid Deployment Mode)

This innovative mobile lithium-ion battery energy storage solution has been developed and manufactured by Northvolt Systems.

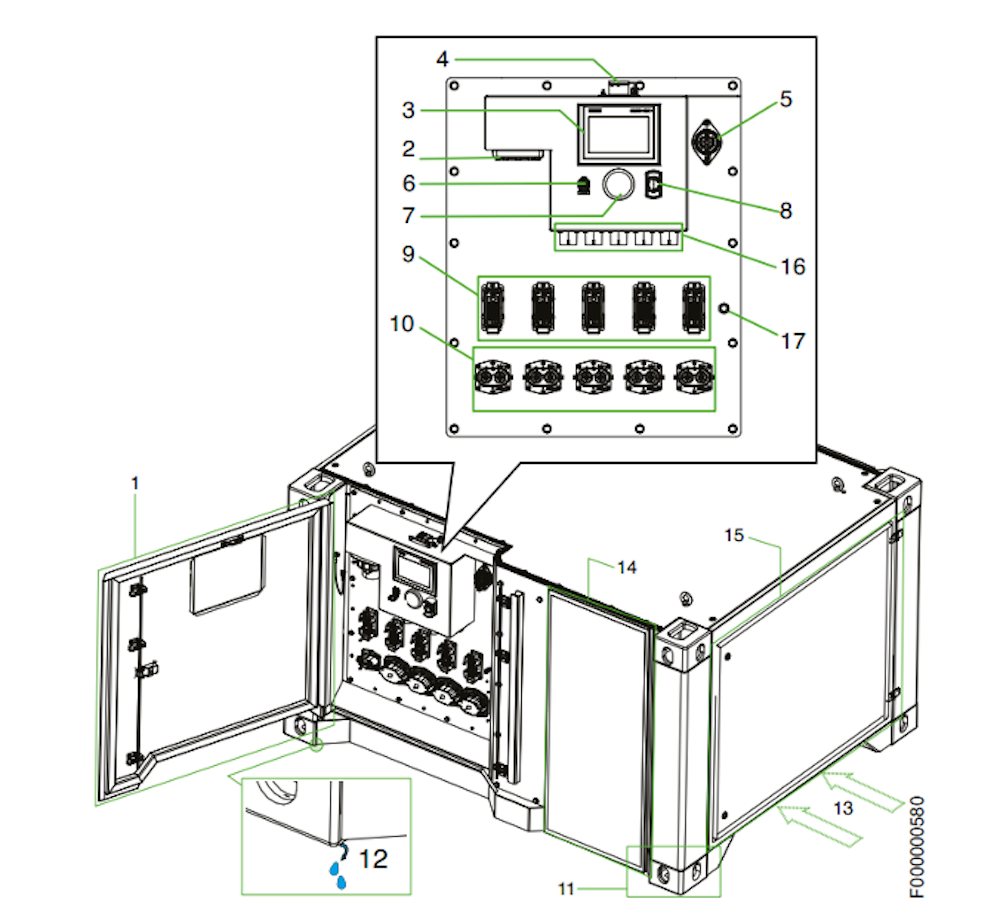

Volthub Grid

- Interlocked connection door: Security, lock the system to power ON

- Three-phase 125 A connector: For Grid connection

- Human-Machine Interface (HMI): Allows control of the system in the easiest way as possible

- Magnetic switch: Security Check if the door is open or close

- Main Switch Disconnect (MSD): Power ON/OFF button

- Ethernet port: For communications with customer control and debug

- Antenna: To send data in the Northcloud and allows Wi-Fi connection. Transmit/receive cloud data and enable wireless connection.

- Emergency stop: Security, disconnect system power in case of emergency

- LV connectors: For VHG to VPM communications and diagnostics

- HV connectors: For VPM to VHG power connection HV DC power connection

- Container corner: Allows plug and play feature with a high mechanical resistance

- Drainage port: Ensure condensation removal

- Forklift space: Allows to move the system with any kind of forklift.

- TMS interface: Air exchange

- Service door: Facilitate replacement and maintenance and ensure a great thermal and mechanical resistance

- Powerlock connectors: Facilitate connection to Grid or Load

- Ground Mains terminal: Connect to external earth thing

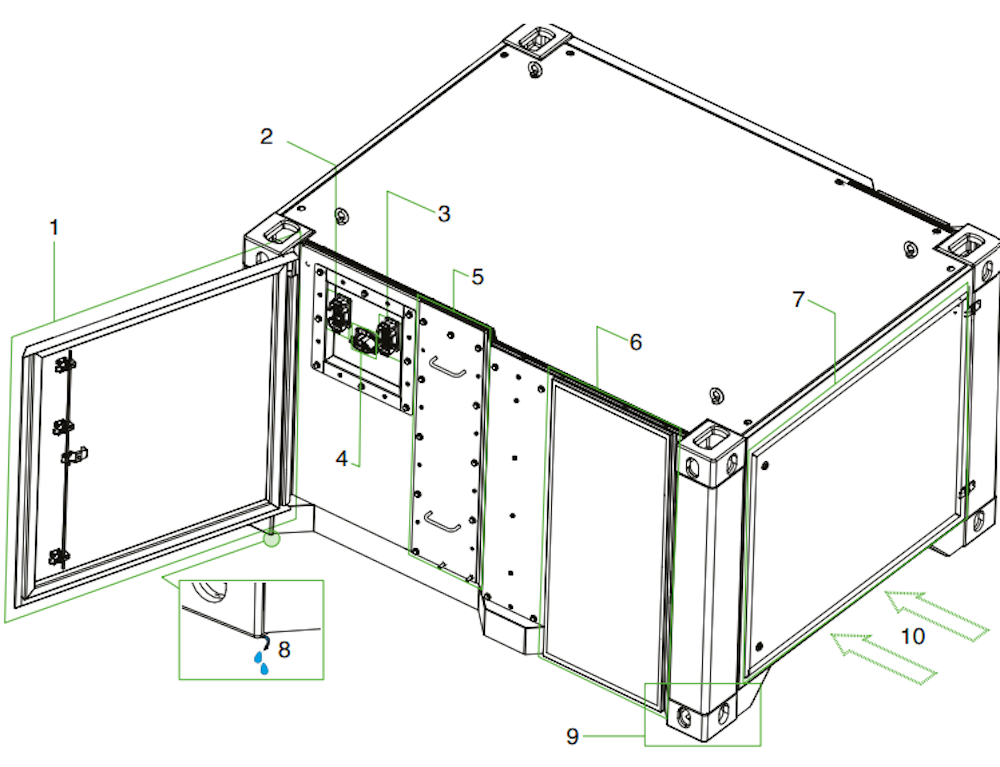

Voltpack Mobile

- Interlocked connection door: Security, lock the system to power ON

- LV connector: For VHG to VPM communications

- Diagnostic connector: For diagnostic case

- HV connector: For VPM to VHG connection

- Service hatch: Facilitate replacement and maintenance

- TMS interface: Air exchange

- Service door: Facilitate replacement and maintenance and ensure a great thermal and mechanical resistance

- Drainage port: Ensure condensation removal

- Container corner: Allows plug and play feature with a high mechanical resistance

- Forklift space: Allows to move the system with any kind of forklift.

3. Applications and integration

The VMS is adaptable and flexible and have several use cases for a large panel of purpose (event, constructions, EV charging and distribution utilities). The adaptability of the VMS allows the system to be one solution for several problems, which is different than being several solutions for one problem. The VMS delivers a BESS which will close the gap between two separately developed markets:

- Temporary power generation.

- Commercial or industrial scale energy storage.

Temporary power generation is predominantly served by diesel generators, resulting in high carbon footprint. Following the increased electrification and green energy transition, new market applications for commercial or industrial scale energy storage will arise.

The innovative features will make the VMS competitive in both the temporary power generation, and commercial or industrial scale energy storage market, while reducing the overall cost of deployment of industrial scale BESS. The VMS has multiple different embedded functionalities and applications, including:

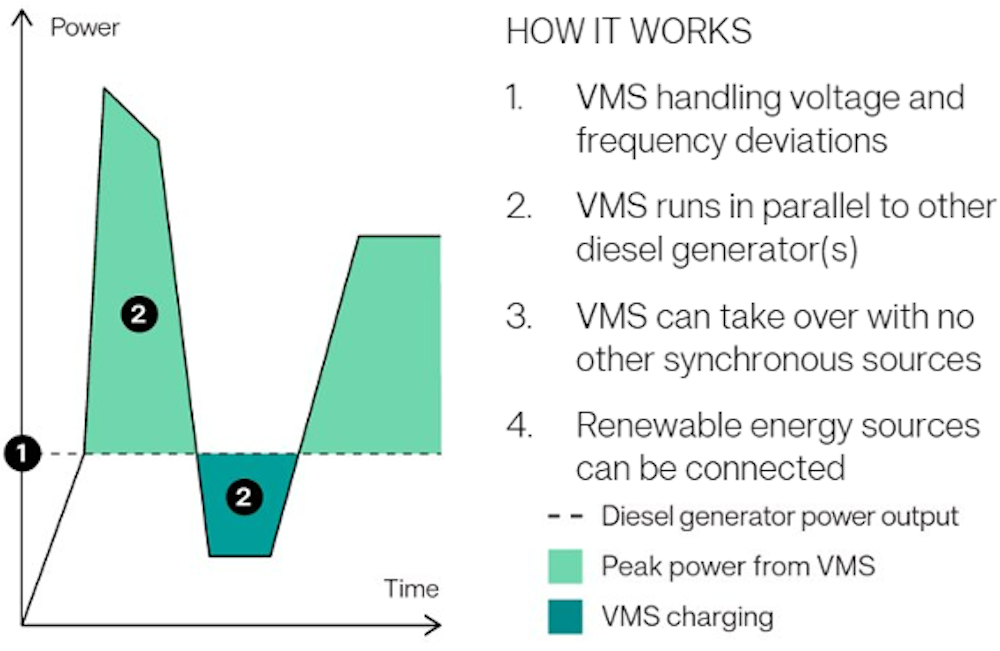

Microgrid mode:

Through a hybrid operation consisting of the combined use of diesel generators and VMS, a reliable and efficient source of power can be achieved. In hybrid mode, the diesel generator provides the base load power, while the VMS provides peak shaving and spinning reserve services. Hybrid operation reduces diesel fuel consumption and diesel generator operating hours. This enables full efficiency and power reliability with smaller scale diesel generators. The VMS can also integrate local renewable power sources. By storing locally produced power from wind turbines or solar panels, the VMS can create a fully stand-alone microgrid and further reduce the consumption of fossil fuel.

Example of use case:

- Deploy in parallel other synchronous sources.

- Increasing fuel efficiency of diesel generators

Rapid peak shave mode: The VMS can support a down-sized grid connection to support transient high-power demands. The VMS can help mitigate the impacts of limited power supply, by providing backup power and energy storage services during times when the grid is unable to meet demand. This helps to ensure a reliable and uninterrupted supply of power.

Example of use case:

- Areas with limited grid power

- High power demand applications (EV charge, crane)

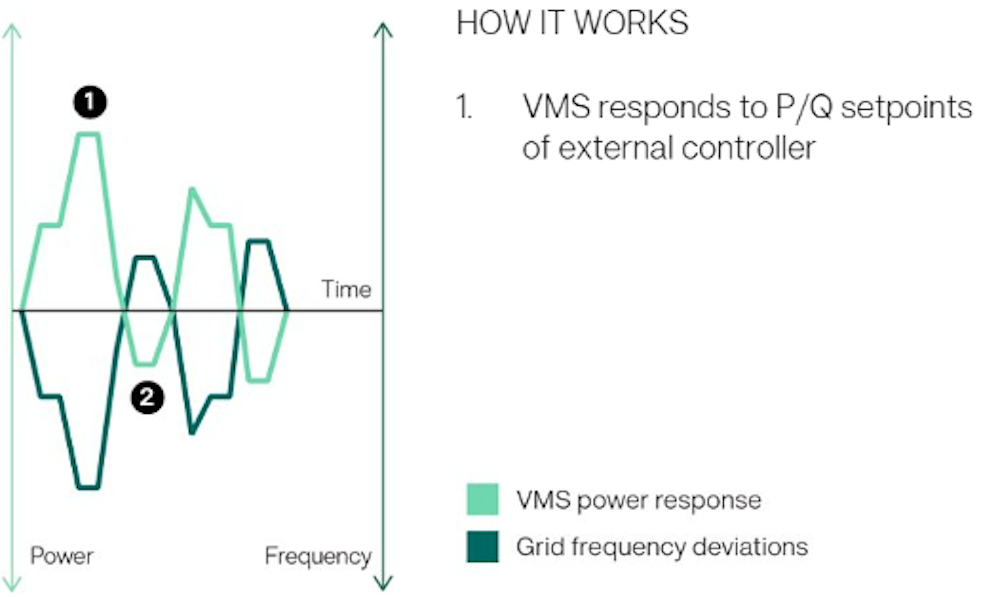

Grid deployment mode: The VMS can enable flexibility by responding to external setpoints of active and reactive power. The VMS can provide ancillary grid services, such as frequency regulation and voltage control, helping to maintain the stability and reliability of the grid. This adds additional revenue streams when the VMS unit is not operating in the field.

Example of use case:

- Operates VMS as a standard grid-connected energy storage

- Create additional revenue stream from frequency reserve markets

Island mode: The VMS can supply power to an off-grid load creating a stand-alone grid. The VMS can enable temporary operation when the grid is unavailable, by providing back-up energy supply to power electric equipment and machinery. This enables electrification also in rural areas.

Example of use case:

- Deploy where no grid connection is available.

- Extend running time with solar or diesel power.

4. Environmental aspects

The VMS project supports the EU’s target to have a transition to renewable electricity supply, while the electricity demand is increasing. With 100% greenhouse gas (GHG) emissions avoidance compared to conventional solutions, the project is on track to help achieve the EU emission reduction targets and to achieve net-zero emissions by 2050.

The planned annual capacity placed on the market, represents a significant potential reduction in GHG emissions and air pollutants. Once the production is fully ramped up, more than 1,165,000 tCO2e net absolute emissions can be avoided during the first ten years of production.

At sector level, the VMS has the potential to contribute to further GHG emission reductions by accelerating the transition to electrified transport and the decarbonisation of the stationary electricity grid.

5. Project design and timeline

The VMS expects to be fully manufactured and designed in Europe, with a fully vertically integrated value chain. With strategically located production facilities, value chain traceability, as well as high ambitions of recycling, Northvolt can ensure both a high level of sustainability and supply security. The NorthFlex project is mainly attributed to Northvolt’s Greenfield factory project in Gdansk, Poland, which is also the Europe’s largest factory for energy storage solutions. This factory reflects Northvolt’s ambition to become a global leader in the development and delivery of premium, sustainable battery solutions for the European market.

Because Securing battery cell manufacturing capacity in Europe is key for its industrial future, the Poland’s factory will receive its supply of lithium-ion battery cells from Northvolt Ett gigafactory, located in Skellefteå, Sweden. To ensure the low emission production, this new factory in Poland will be powered with renewable energy, including on-site renewable energy generation.

The NorthFlex Project will allow an entirely new market for energy storage, one that can service the fast-growing need for electrification through rapid deployment, while offering a wholescale sustainable replacement for diesel gensets.

- Project start date - April 2021

- Field Pilot Program completion - Q3 2021

- Entry into Operations - Q2 2024

Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or CINEA. Neither the European Union nor the granting authority can be held responsible for them.