With Northvolt’s recycling process, we’re able to recover battery-grade metals with a much lower carbon footprint than freshly mined metals. Gram for gram, cathode material produced from Revolt recycled material has a carbon footprint that’s 80% lower than industry average.

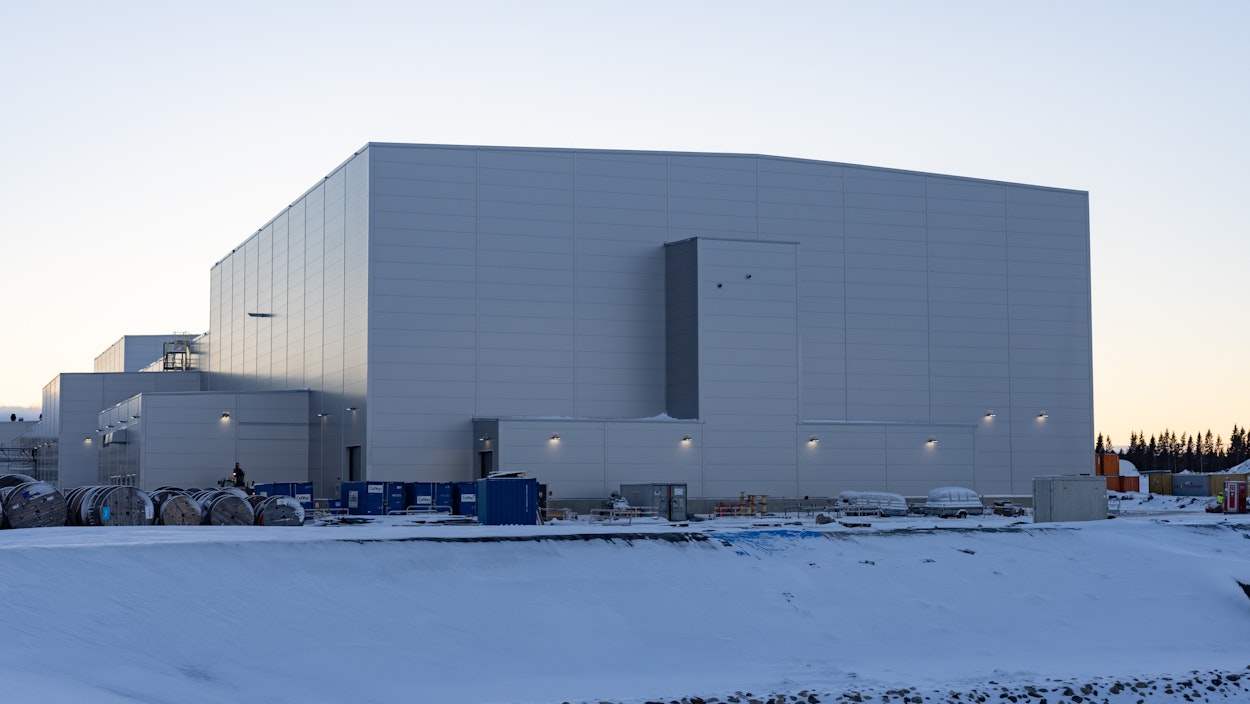

Revolt

Recycling Lithium-ion batteries

The world needs sustainable batteries. And a plan for what to do with them at end-of-life. Our solution: take old batteries and turn them into fresh raw materials for batteries of tomorrow. We do this through Revolt – our program for battery recycling.